Tooling Integration

Connecting various tools and equipment with automation systems.

By seamlessly connecting various tools and equipment with automation systems, tooling integration transforms the way manufacturing operations are conducted.

Integration of Servo Presses

Improve process efficiency and minimize the risk of defective parts

Integration of Hydraulic Presses

Exert consistent pressure throughout repetitive tasks ensures optimal end-product quality

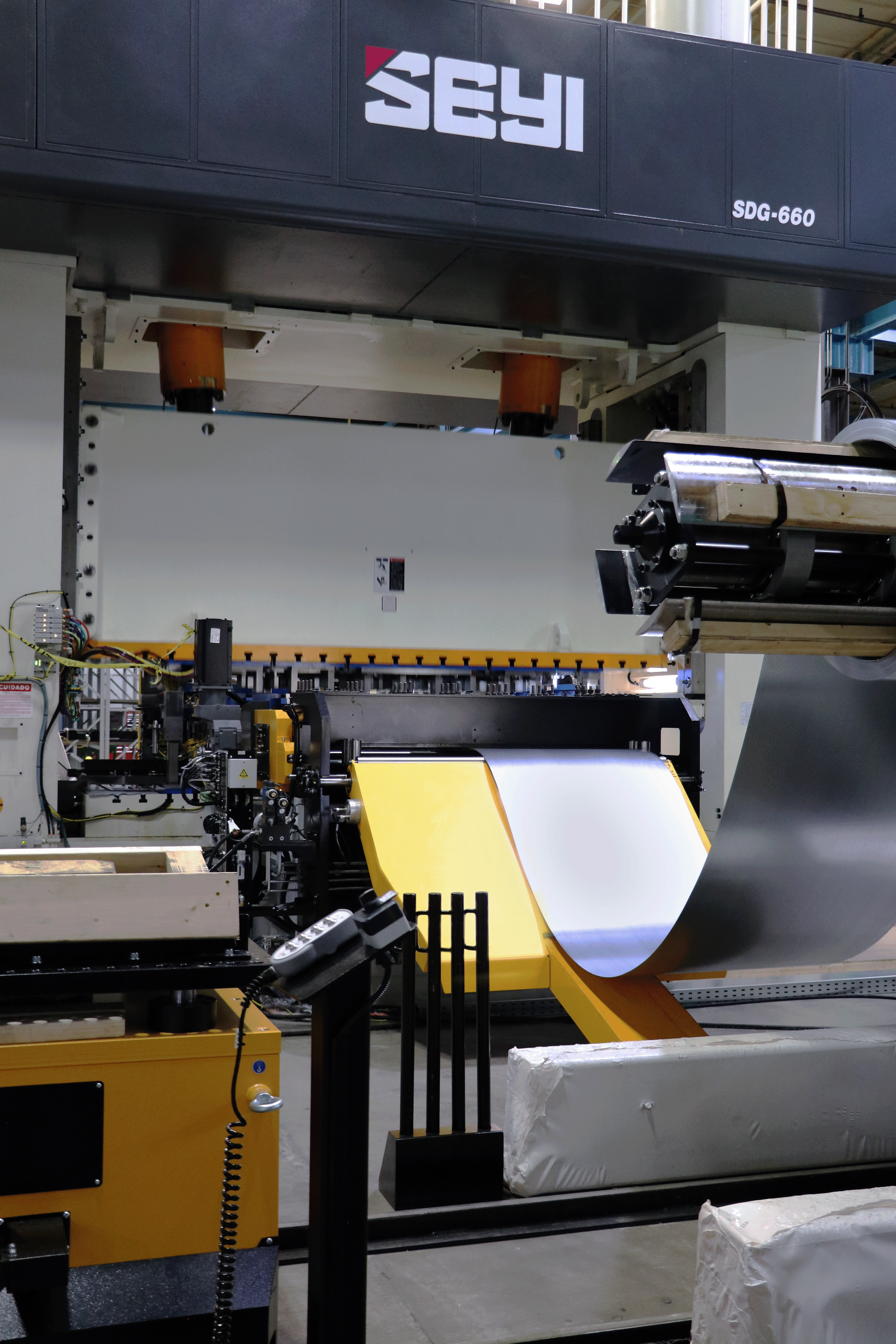

Servo Feed Systems

Automating tasks requiring intricate material handling, such as cutting, punching, or stamping operations

Integrating Servo Presses

These presses utilize closed-loop control systems, enabling operators to achieve precise force control, position accuracy, and speed modulation. With their customizable profiles, they empower manufacturers to perform complex operations, such as assembly, riveting, and forming, with exceptional reliability. The integration of servo presses ensures consistent and accurate force application, resulting in enhanced product quality and reduced waste. Additionally, servo presses offer flexibility, as they can be easily programmed to accommodate different materials, shapes, and sizes, thus reducing changeover time. With their ability to monitor and adjust force levels in real-time, servo presses improve process efficiency and minimize the risk of defective parts. As a result, industrial automation systems incorporating servo presses effectively streamline production, improve productivity, and strengthen overall manufacturing capabilities.

Integrating Hydraulic Presses

Hydraulic presses are widely renowned for their immense force capabilities. These robust machines efficiently generate high hydraulic pressure that translates into superior strength and performance. Due to their immense power output, hydraulic presses excel in heavy-duty applications like metal forming, deep drawing, and shear cutting. Their ability to exert consistent pressure throughout repetitive tasks ensures optimal end-product quality. The addition of hydraulic presses, known for their excellent power-to-die proximity efficiency, further enhances energy utilization. This ecological benefit not only minimizes costs but also aligns with sustainable manufacturing practices.

Integrating Servo Feed Systems

By utilizing servo motors and controllers, servo feed systems effectively regulate the speed and position of material feed, ensuring optimal accuracy and consistency. The integration of these systems into the automation workflow empowers manufacturers to automate complex tasks that require intricate material handling, such as cutting, punching, or stamping operations. Moreover, by seamlessly connecting servo feed systems with other automation equipment, such as robotic arms or CNC machines, manufacturers can achieve seamless coordination, resulting in improved performance and reduced downtime. Overall, the integration of servo feed systems in industrial automation paves the way for enhanced productivity, superior product quality, and greater cost-effectiveness.