System Integration and Technology

Seamlessly connecting and optimizing manufacturing processes.

Leveraging cutting-edge technology and best practices to optimize processes and drive innovation.

At DT Engineering, we specialize in industrial automation integration, leveraging cutting-edge technologies and best practices to enhance efficiency, reduce costs, and drive innovation. Our expertise in system integrations enables manufacturers to streamline production to become scalable.

Significant Operational Benefits

By partnering with top technology integrators, manufacturers can seamlessly connect their automation systems, ensuring smooth, and reliable operations. Effective system integration in industrial automation delivers significant benefits, including:

increased operational efficiency

reduced downtime

enhanced safety

improved quality control

optimized resource utilization.

Foundation for Industry 4.0

Unlock the full potential of industrial automation, allowing businesses to remain competitive in a rapidly evolving market. As a leading system integration company, DT Engineering helps manufacturers transition to Industry 4.0 by integrating:

predictive analytics

machine learning

autonomous control.

Flexibility and Scalability

Our automation system integrations ensure that manufacturers maintain peak efficiency while scaling their production capabilities. With our control system integrators, businesses can:

upgrade and expand operations without disruptions

seamlessly merge new advanced integrated tooling solutions

improve adaptability to meet changing industry demands.

DT Engineering: A Trusted Industrial Automation System Integrator

Our team of system integration experts develop tailor-made solutions that transform manufacturing processes. With our deep understanding of diverse automation systems and proven expertise in seamless implementation, we leverage cutting-edge technology and best practices to optimize processes and drive innovation.

As a leading industrial automation system integrator, we understand the intricate complexities that manufacturers face. Whether it is streamlining production lines, improving control systems, or implementing innovative solutions, we are dedicated to solving the most pressing challenges faced by our customers across various industries.

The Power of Integration

System integration in industrial automation is the backbone of a smart factory, where there is seamless connectivity between automation systems. Leveraging the power of integration delivers increased efficiency, reduced costs, improved safety, and enhanced productivity, empowering companies to remain competitive in an ever-evolving industrial landscape.

Utilize Machine Vision, Optics, and Scanning Systems to Improve Productivity and Reliability

Rule Based Vision

Measurement and Gauging

Location and Fixturing

Robotic Guidance

Presence/Absence

Edge Learning

Classification/Sorting

Assembly Verification

Character Reading

Deep Learning

Complex Defect Detection

Tasks with Significant Variations

Highly Customized Jobs

3D Volumetric Measurement

Clear/Translucent Part Applications

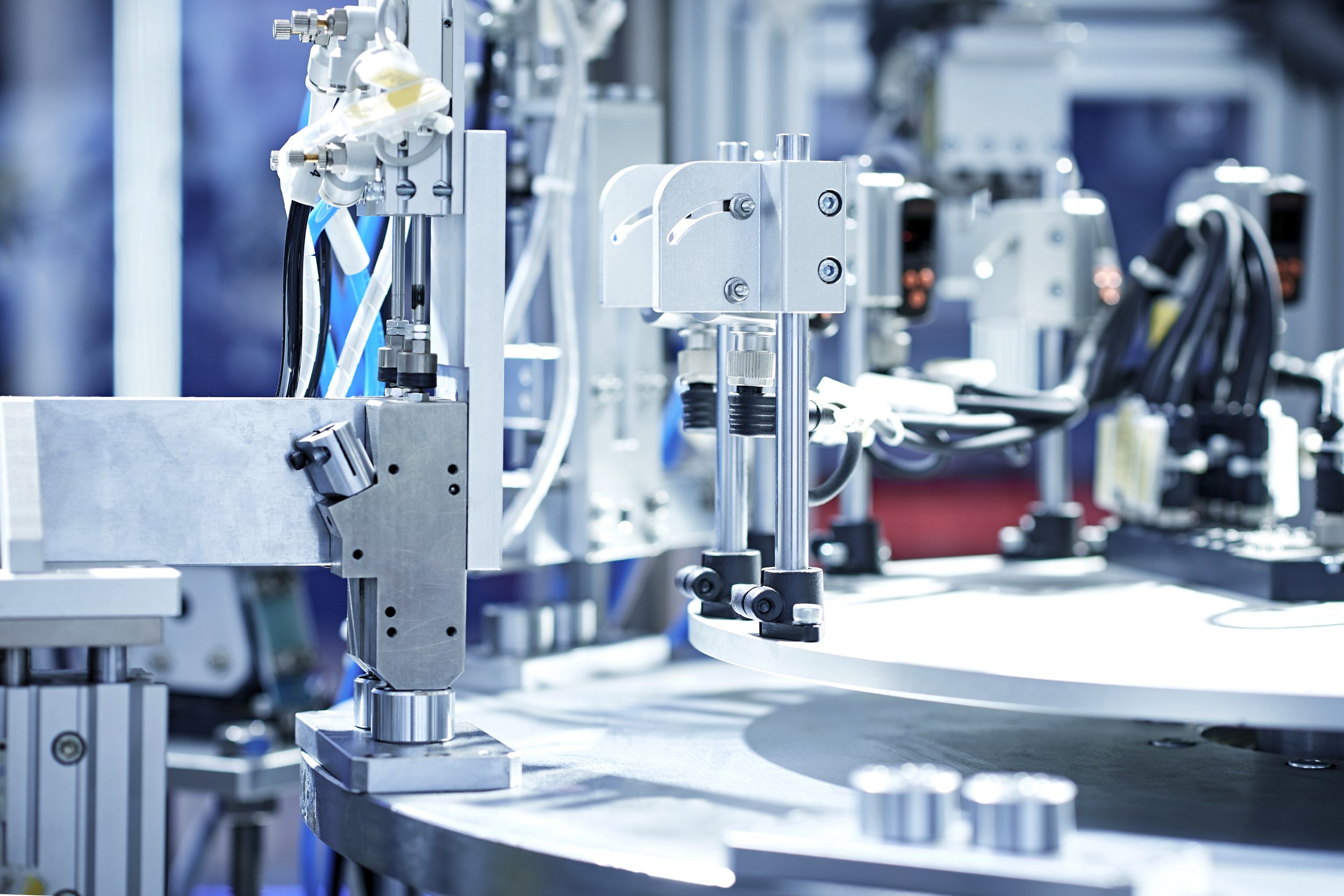

System Integration facilitates seamless coordination

among various components such as robots, vision systems, and smart conveyance. With the expertise of control system integrators, manufacturers can achieve higher levels of productivity, efficiency, and accuracy on the manufacturing floor.

Robots are employed to perform repetitive tasks with precision, eliminating the risk of human error and reducing cycle times.

Vision systems, equipped with advanced cameras and image processing, provide real-time feedback to robots, ensuring precise positioning, inspection, and quality control.

Smart conveyance systems provide efficient transportation of products between workstations, optimizing workflow and minimizing bottlenecks.

The integration of these technologies enhances overall system flexibility and adaptability, enabling industries to meet the demands of a rapidly changing market.

Stay ahead of the curve

As an experienced system integrator,

we diligently consider factors like scalability and sustainability in every solution we provide.

DT Engineering’s commitment to exceptional customer service doesn’t end with implementation. We provide comprehensive training, ongoing technical support and maintenance services to ensure our automation integration and advanced tooling solutions operate at peak performance, empowering manufacturers to achieve their production goals.