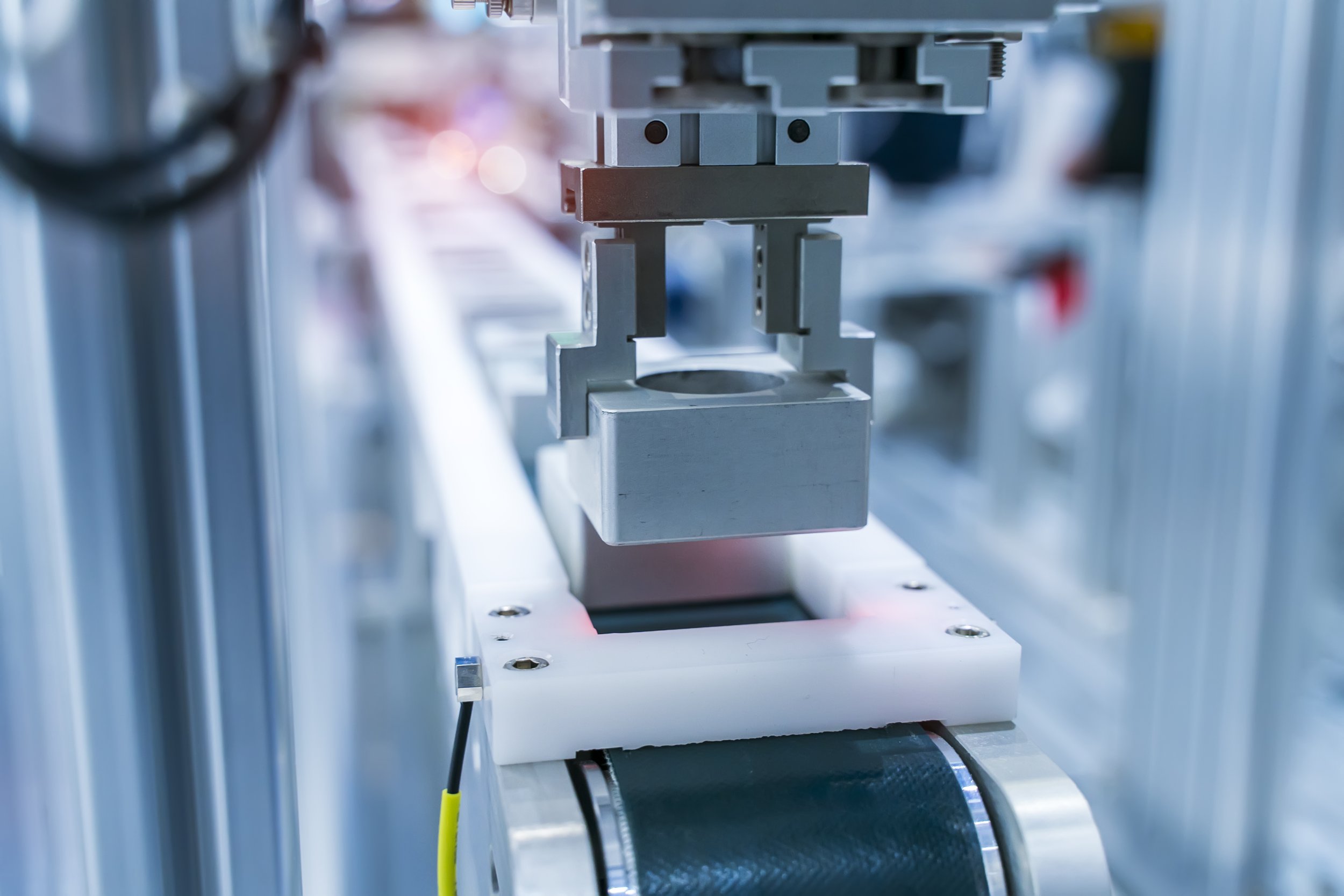

Assembly Tooling

Ensuring streamlined production processes and achieving optimal efficiency.

DT Engineering’s tooling is custom-built to ensure higher accuracy, repeatability, reduced changeover time, and high flexibility for mixed product run.

Part Nesting

Part nesting reduces the need for individual setups, saving valuable time and resources. It allows for simultaneous process of multiple components, ensuring consistent quality across the assembly line.

Cam-Driven Mechanisms

These systems offer exceptional control, repeatability, and adjustability, enabling the automation of complex assembly processes, allowing higher volumes, superior consistency, and reduced production cost.

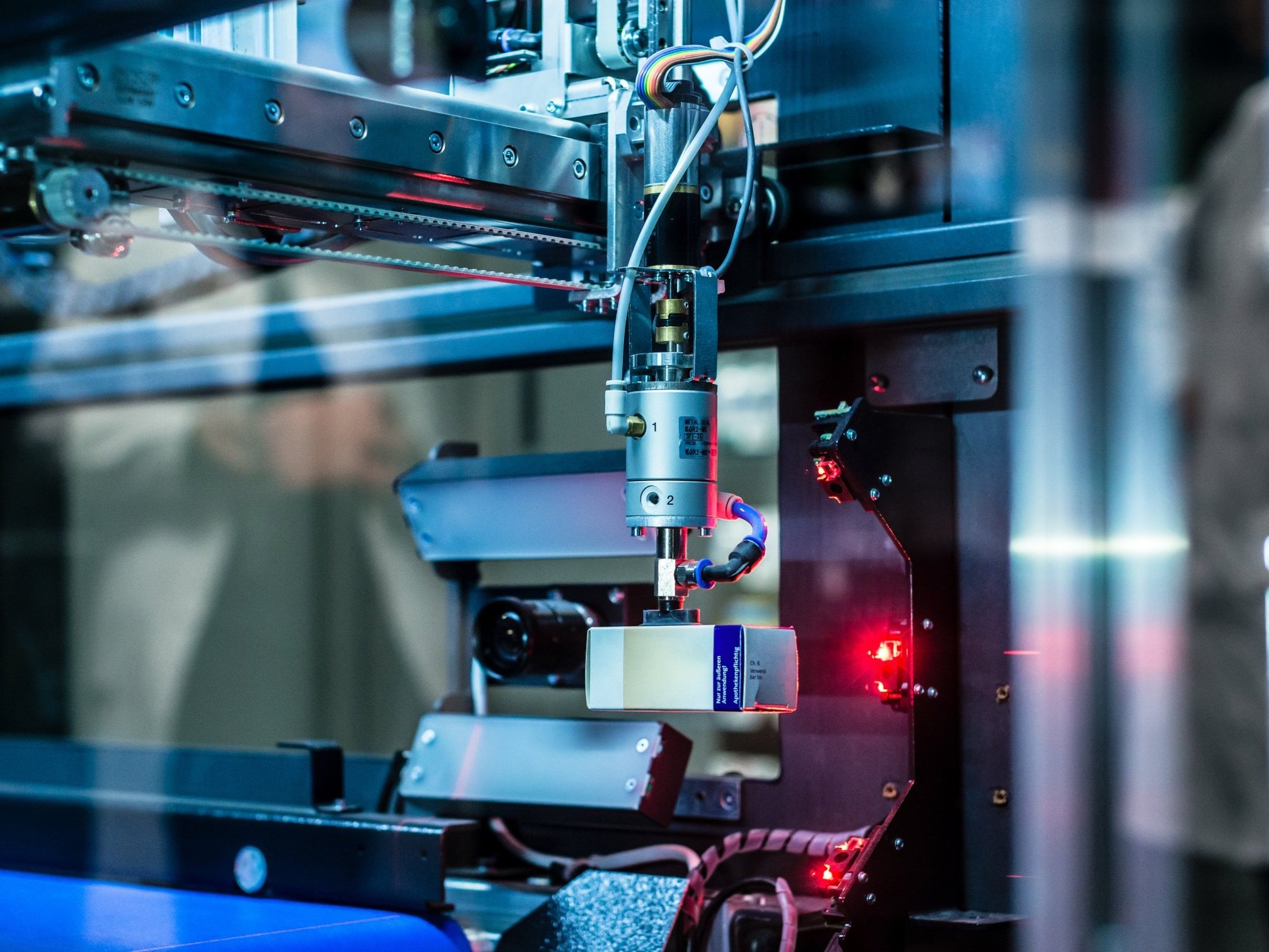

Part Identification Systems

Part identification expedites assembly processes, enhances overall efficiency, and minimizes waste by incorporating technologies like barcode scanners, RFID readers, and vision systems to track and sort components.

Assembly Tooling

In the world of industrial automation, assembly tooling plays a pivotal role in ensuring streamlined production processes and achieving optimal efficiency. From part nesting to cam-driven mechanisms and part identification systems, these advanced tools are transforming the manufacturing landscape.

As technology continues to advance, assembly tooling is reaching new heights of innovation and enabling manufacturers to achieve unmatched efficiency, accuracy, and productivity. The future of industrial automation holds even greater promise as these tools evolve, redefine production processes, and accelerate the pace of innovation.