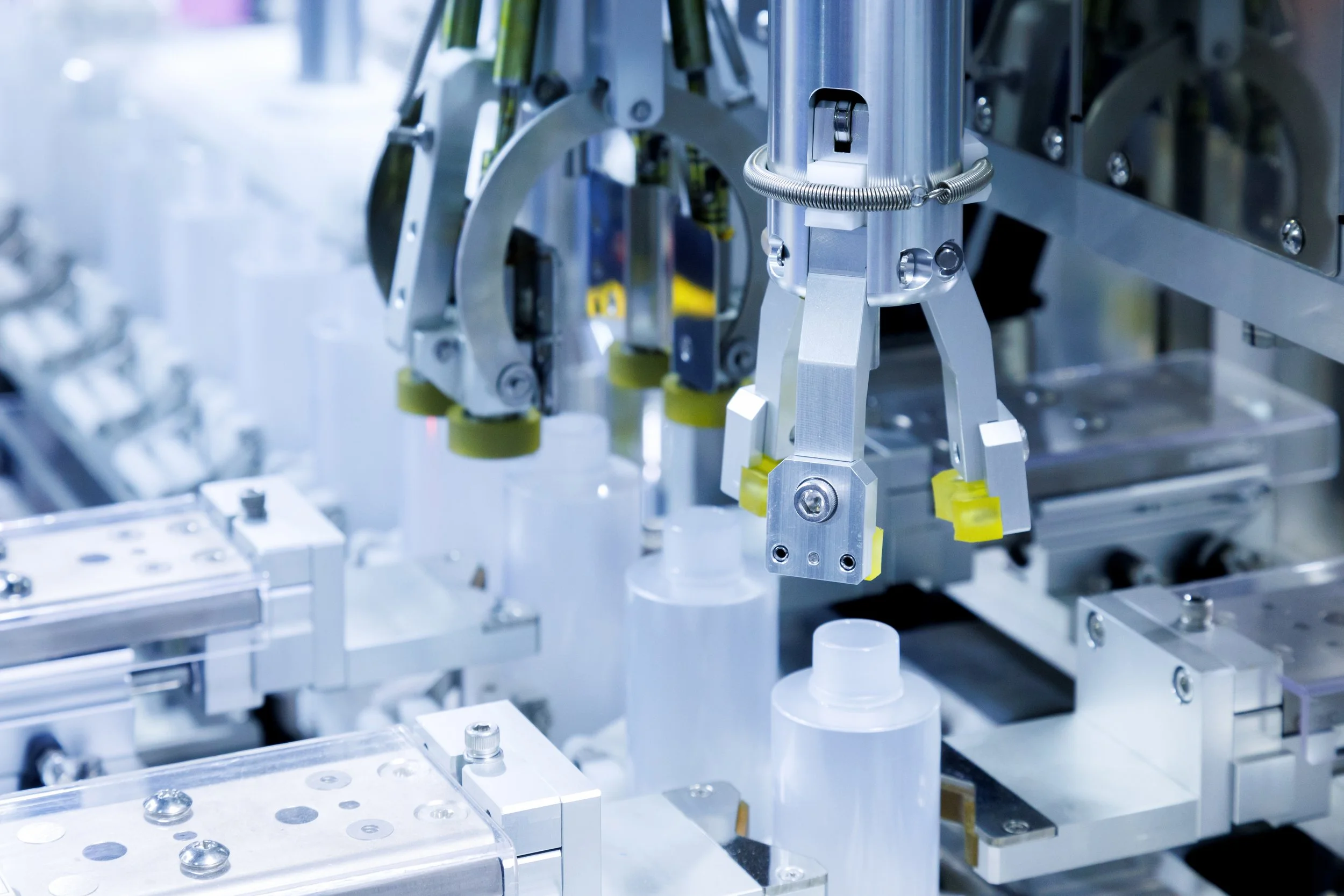

Robotic End of Arm Tooling

Indispensable in streamlining manufacturing processes.

Robotic End of Arm Tooling – Grippers

Robotic End of Arm Tooling (EOAT) grippers play a vital role in industrial robotic automation, enhancing the versatility and efficiency of robotic systems. Robot grippers are collaborative subassemblies mounted to the end of a robotic arm, enabling the robot to interact and manipulate objects across a range of robotic process automation applications. EOAT grippers come in diverse designs, including pneumatic, hydraulic, and electric variants, each tailored to accomplish specific tasks in a variety of environments. From industrial assembly to material handling, EOAT grippers are indispensable robotic automation tools, improving productivity and accuracy in today’s automation-driven industries.

Robotic End of Arm Tooling – Torquing

The process of torquing involves the precise application of torque by a robotic arm to various components or fasteners. Robotic EOAT allows for the automation of torque application, eliminating the need for manual labor and increasing productivity. These end effectors are designed to provide controlled torque levels and prevent over-tightening or under-tightening. In manufacturing and assembly processes, the torquing process in robotic end of arm tooling offers a reliable and efficient solution for achieving consistent and accurate torque application in various manufacturing and assembly processes.

Robotic End of Arm Tooling Processes

Specialized Cutting Tools

Through the use of advanced robotic automation, robotic arms equipped with cutting tools can follow predetermined paths and adjust cutting parameters on the fly. This capability makes end of arm tooling an invaluable asset in manufacturing processes.

Advanced Inspection Tools

These tools with integrated inspection technology can accurately detect any signs of wear, damage, or misalignment in the EOAT, ensuring that it operates optimally and minimizes any potential production disruptions.

Equipped Welding Tools

The end of arm tooling can be customized to adapt to a wide range of welding requirements, delivering consistent weld quality across various materials and joint configurations.

Highly-Efficient Spraying Tools

This tooling can achieve consistent and controlled coating applications allowing for automated and uniform spraying of paints, coatings, adhesives, or other substances onto surfaces.