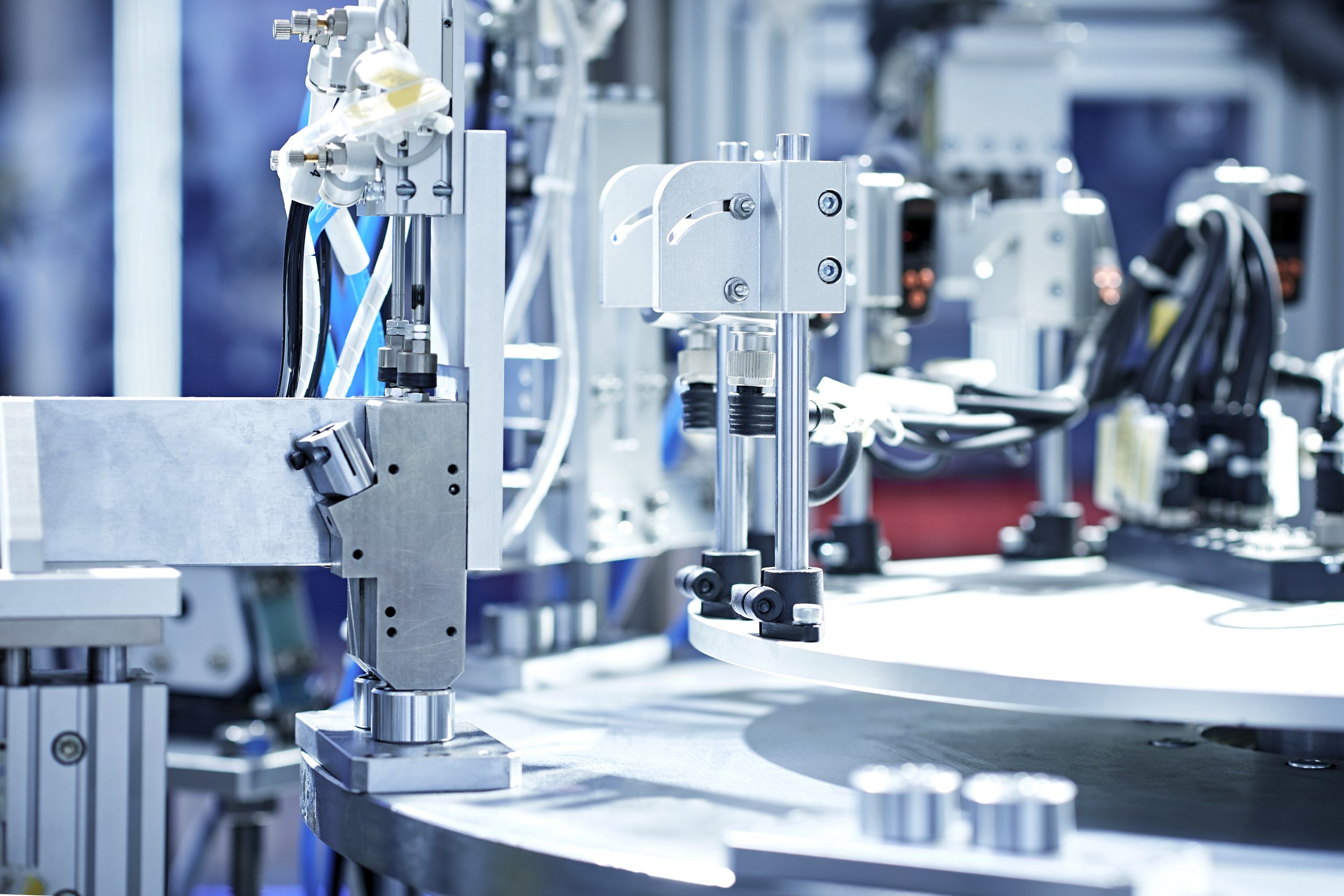

Medical Device Industrial Automation Systems

Automation Built for Medical Device Excellence

We develop cutting-edge medical device automation solutions that revolutionize manufacturing. Our industrial automation production systems ensure scalable, compliance-ready precision, efficiency, and traceability, helping medical device manufacturers reduce costs, accelerate production, and maintain regulatory excellence.

As a leading industrial automation company, we offer deep industry expertise, AI-powered insights, and dedicated customer support designed for the evolving demands of the medical device assembly industry. We don’t just build machines—we build long-term partnerships for success.

Our Capabilities

Therapeutic Devices

Surgical Tools

Medical Delivery

Fitness & Wellness Devices

Diagnostic Devices

Rehabilitation Assistive

Devices

Key Benefits of Automation in Medical Device Manufacturing

Implementing medical device automation solutions ensures unparalleled precision, regulatory compliance, and production efficiency. By reducing human error, increasing consistency, and streamlining workflows, industrial automation enhances product quality, faster production, and lowering costs.

Advanced robotics and predictive analytics minimize downtime, improve worker safety, and accelerate time-to-market. With scalable, flexible medical device assembly solutions, manufacturers can quickly adapt to evolving industry demands—ensuring higher output, reduced waste, and superior reliability in every device produced.

Enhance Quality. Reduce Costs.

Automate with Confidence.

At DT Engineering, we go beyond automation—we deliver a seamless customer experience tailored to the unique needs of the medical device automation industry. From FDA-compliant solutions to cutting-edge robotics, we ensure your production lines operate with superior reliability and efficiency.

With deep industry expertise and a commitment to innovation, we help manufacturers scale faster, maintain compliance, and gain a competitive edge.

Unmatched Precision

Achieve extreme accuracy and consistency with medical device assembly automation.

Regulatory Compliance

Meet FDA and ISO 13485 standards effortlessly, to ensure patient safety, product reliability, and quality control.

Faster Production, Lower Costs

Increase efficiency while cutting operational expenses with industry automation technologies, allowing you to stay competitive and deliver high-quality products faster.

Compliance Ready

Pre-certified, regulation-ready machines with pre-validation solutions. Reduce time-to-market by 15 months.

Non-Compliance Monitoring

Real-time monitoring and alerting using advanced vision and AI technologies.

Documentation Automation

AI powered audit and reporting tools, 21CFR Part 11 Compliance coding practices.

Cybersecurity Shield

Controls Systems designed with zero tolerance to cyber attacks.

Seamless Validation to Meet FDA Requirements

When partnering with DT Engineering and Sterling Engineering you’ll reduce your time and resource investment, while capitalizing on our knowledge and expertise in Life Science equipment. We can provide commissioning assistance of equipment for SAT/FAT and assembly process equipment validation. Our documentation package includes: DQ, SQ, IQ, and OQ. We have deep experience in executing assembly validation processes to help meet FDA requirements.

We provide a complete qualification document package.

Proof of Our Success

Breaking Barriers: How Our Proof of Concept Validated Automation for a Prominent Healthcare Company

In high-speed medical automation, precision and efficiency are non-negotiables. But finding an automation company who can truly deliver is a challenge. That’s why we don’t just promise results—we prove them.

For a leading medical device manufacturer, we designed and tested a high-speed robotic automation system that:

minimized product handling,

achieved 350 parts per minute,

and cut validation time by 40%—all before full commitment.

Ready to see what’s possible for your medical device production line? Let’s prove it.